The Duke Robotics Club makes significant use of 3D printing to design and prototype crucial components for the team’s AUV. The demands of the club are difficult to keep up with, as club members print around the clock in the Co-Lab and the Foundry to stay on schedule with the pool tests. The need for faster and higher-quality prints urged the team to obtain their own 3D printer, which would enable larger print volumes and more design freedom. After weeks of browsing and consultation, the club decided to order the Daedalus 3D Printer from Project R3D. Reviews of the printer were promising and the company had a good reputation for exceptional printers. Our sights were set on buying this printer and we patiently awaited its arrival.

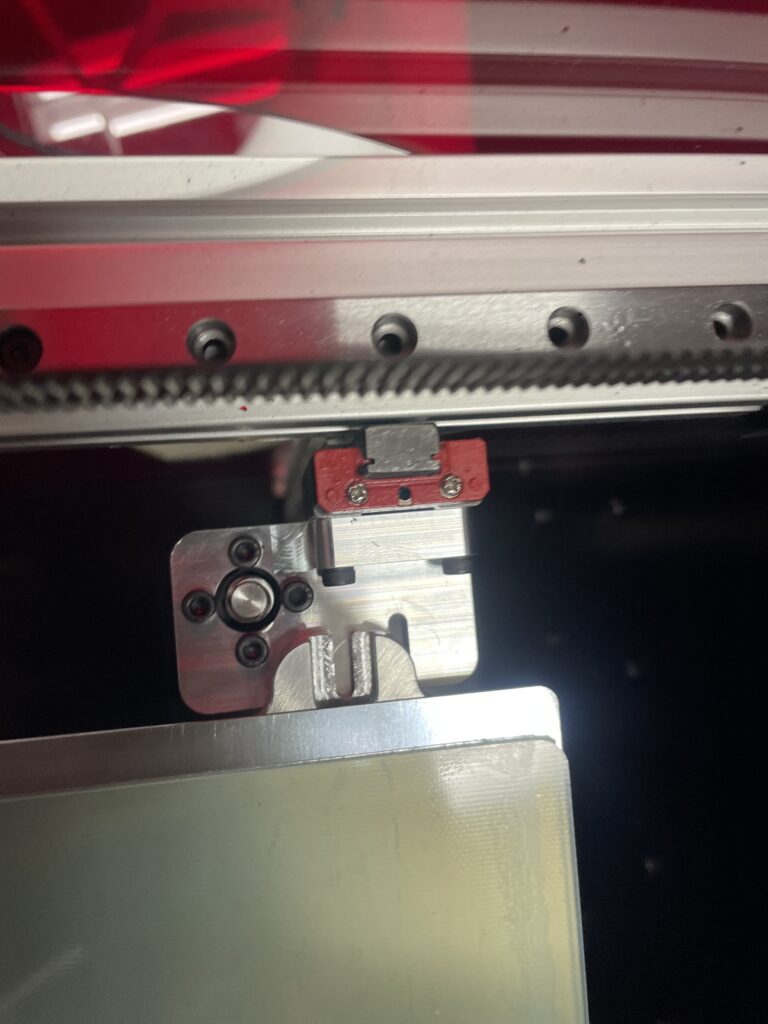

The printer finally arrived in June. Conveniently, a robotics member was on duty over the summer and took on the task of assembling the printer. The condition of the package was worrying since in classic UPS tradition, it was delivered with a giant hole punched into the box. Despite this, we kept our hopes high and continued on with the printer.

Upon taking the printer out of the package, we found that one of the acrylic walls was completely shattered.

Again, we kept our hopes high. The tutorial for assembling the printer was very straightforward and easy to follow. Unfortunately, while calibrating the print bed, a loud snap was heard and it was discovered that one of the lead screws was bent, rendering the printer completely unusable.

We are still in the process of getting a refund and attempting to order another 3D printer.