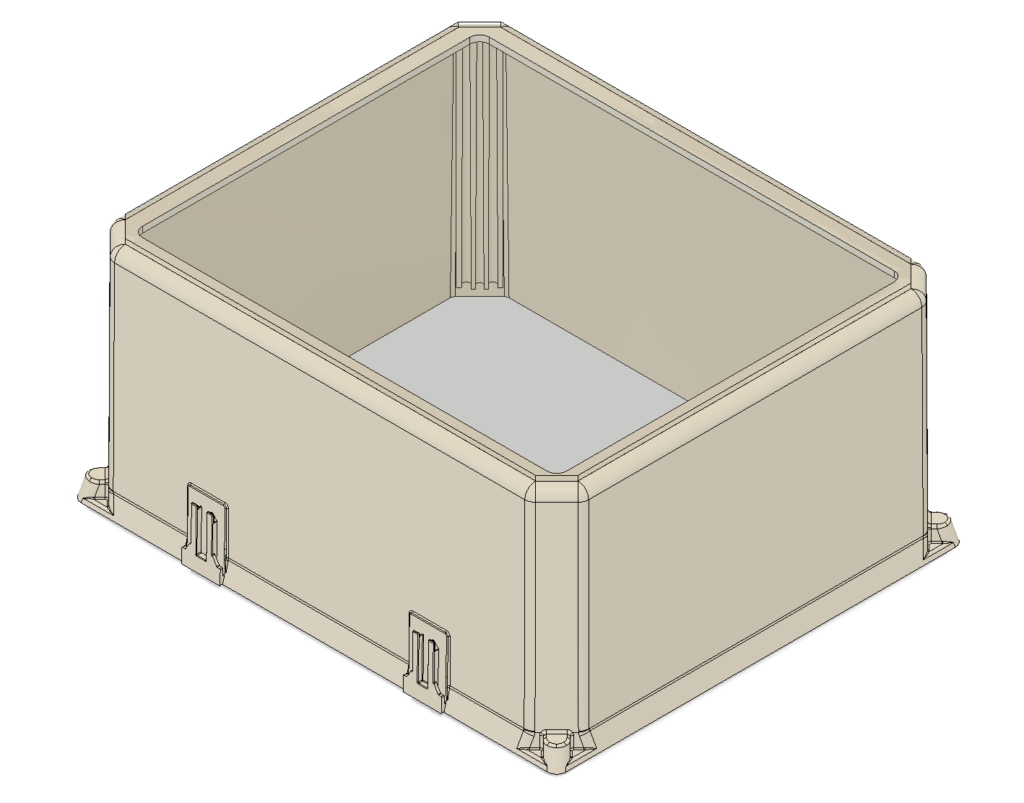

Last year, we used a standard Polycase™ waterproof enclosure to house our electrical stack and keep water out. This capsule came with four brass inserts in the corners to press the capsule into the O-ring.

Despite working initially, wear and tear from a year of use eventually degraded the plastic-brass bond, causing the brass inserts to come out or crack the plastic at the corners of the capsule. This problem was exacerbated by the depth of the pool at TRANSDEC. During testing, we usually didn’t go very deep, and the water pressure at competition meant the plastic corners were much more susceptible to cracking.

We had several temporary solutions we pursued at the competition, such as coating the plastic corners with epoxy or replacing the brass inserts with a through-hole. However, none of these solutions were perfect and would not be able to preserve the watertightness of the capsule in the long term.

While less significant, another major problem we had with our capsule was the complexity of the installation. All four screws are found on the bottom of the robot, and require the capsule to be perfectly lined up to go in. Because of this, it can often take upwards of five minutes to screw in the capsule. This is extremely problematic for testing, as we often need to lift the capsule to work on the electrical stack.