This past week marked a major milestone for our mechanical team — we successfully onboarded all our new members! Each student was matched with a project aligned with their interests and skillsets, ensuring everyone gets hands-on experience from the start.

The major projects currently in development include: capsule cooling, additional thrusters for Crush, a marker dropper, new servo gripper, and redesigned Oogway capsule mounts.

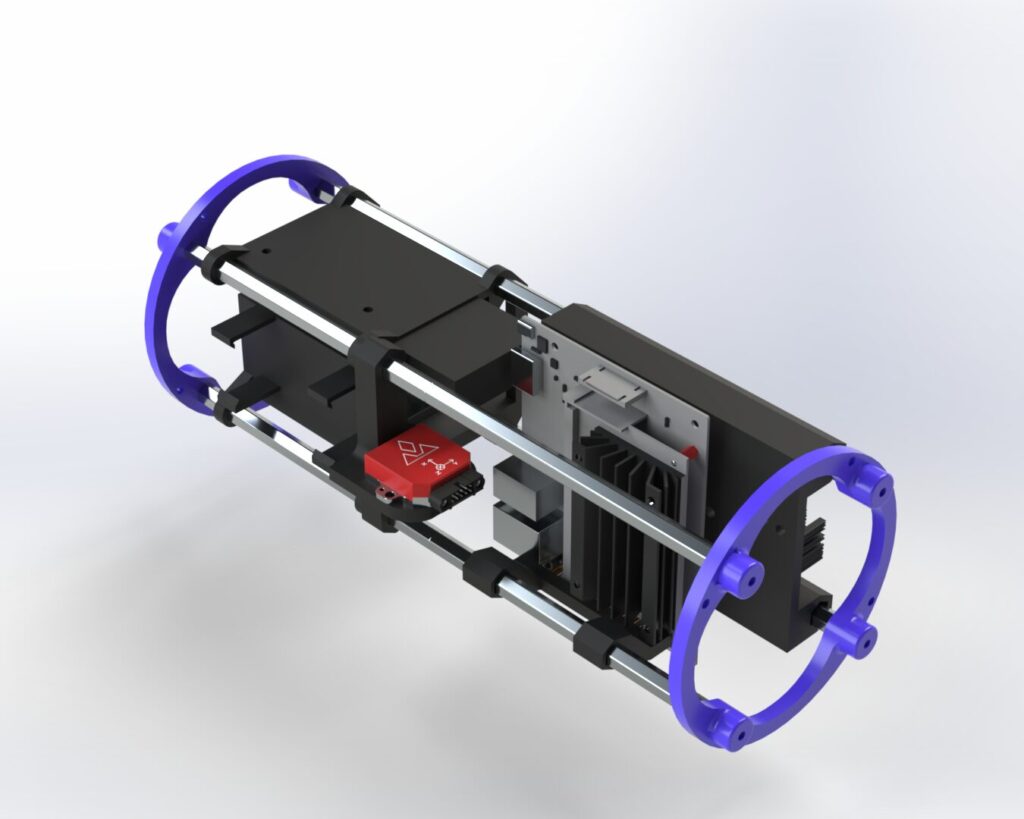

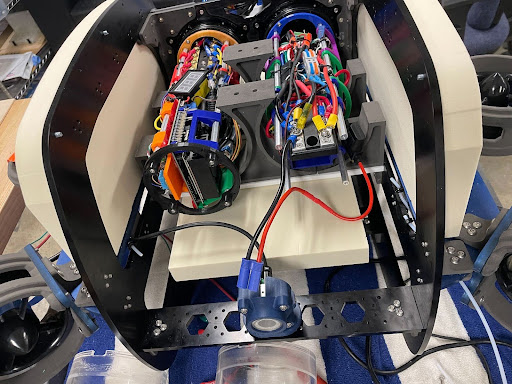

Capsule Cooling

Heat management has been one of our ongoing challenges, and we’re tackling it with a two-part redesign. The plan is to add fans at the front and back of the capsule to improve airflow. To further enhance cooling, we’re redesigning the front cover and back plate in metal, integrating heatsinks to transfer and distribute heat more effectively into the frame.

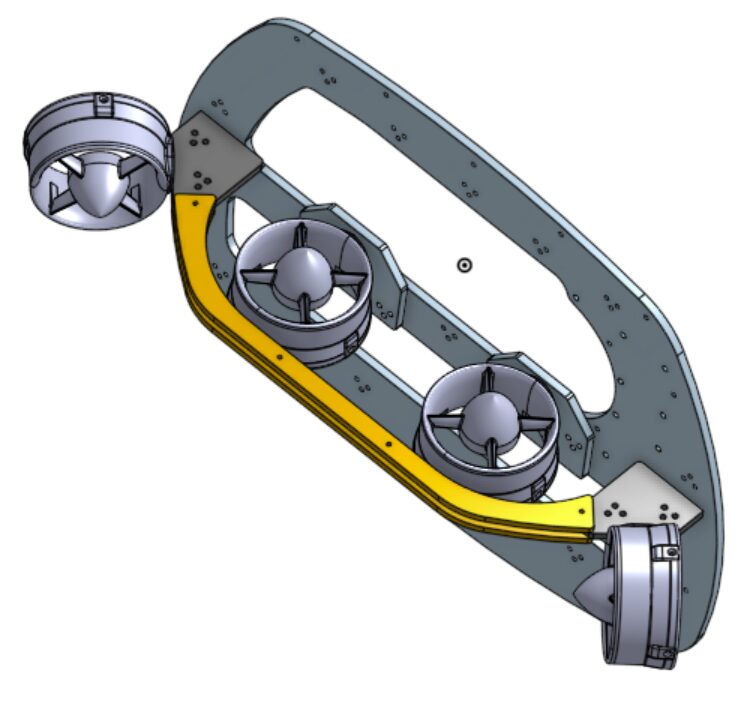

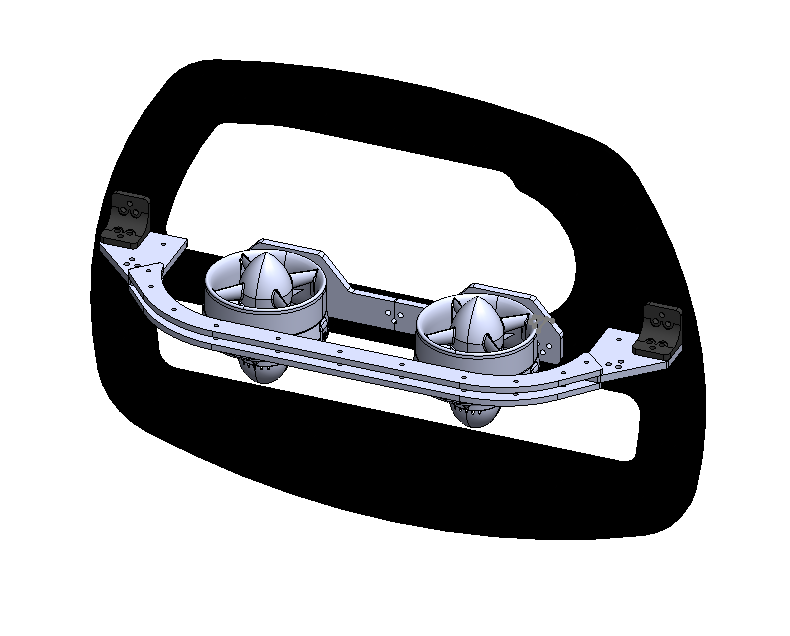

Thrusters on Crush

After weighing several ideas, the team decided on a lightweight solution that makes use of the existing mounting holes. The new design will add two thrusters on each side of Crush, bringing the total to eight. This setup maximizes power and allows for pitch control without unnecessary weight or complexity. Two mounting designs are still be to tested to make sure there aren’t any structural issues.

Oogway Capsule Mounts

Our team member Ivan has been busy refining the capsule mounts to make them stronger and easier to use. One recurring issue has been the camera capsules rotating during operation. The new design introduces grooves on both sides to prevent rotation and allows the same part to be used on either side of the capsule, regardless of orientation.

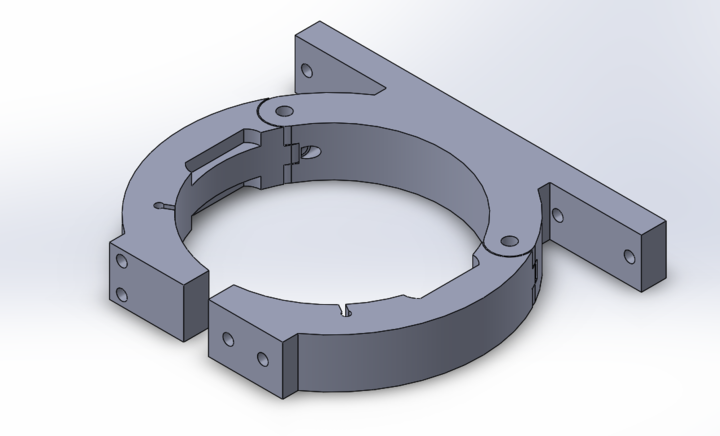

Marker Dropper

The marker dropper is also moving forward with a compact and simplified redesign. It will be mounted on Crush and capable of releasing two markers at a time — important since two must be dropped in the same location. The team is currently brainstorming solutions with servo size, finding accessible mounting areas on the frame, and ensuring the markers don’t collide with each other mid-drop. In addition, new marker designs are being tested for reliability and accuracy!

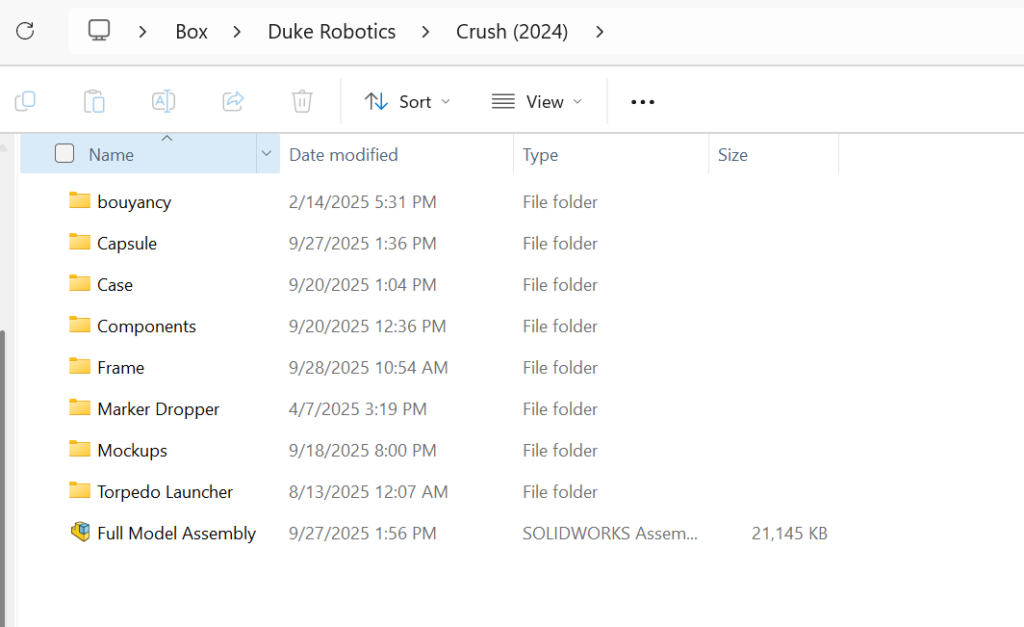

CAD Organization

Behind the scenes, another group has been working hard to organize our CAD files in Box Drive. This effort may not be flashy, but it’s essential to keeping the team efficient and ensuring our designs are easy to access and build upon.

This week has been full of momentum, with new members contributing fresh ideas and our core projects making significant progress. We’re excited to see these upgrades come to life and can’t wait to share more soon.