These past weeks the Mechanical team has been hard at work with a multitude of projects including installing the thruster cable injector, changing propeller configurations, new gripper design, and a few others.

Thrusters on Crush

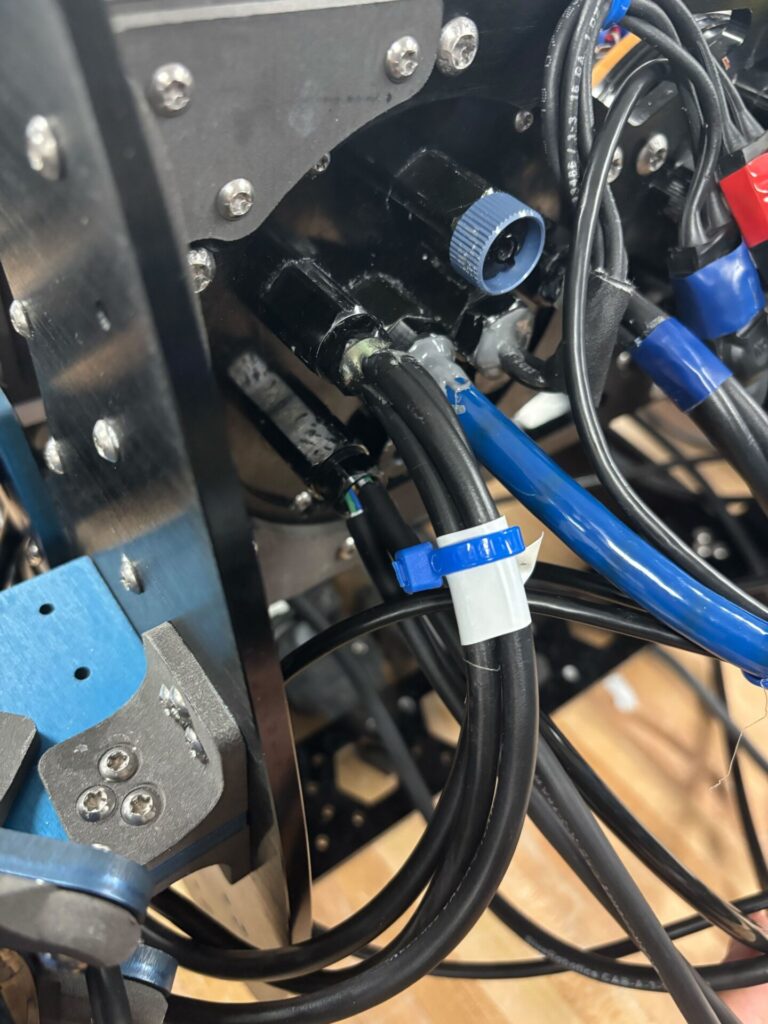

All eight thrusters have been mounted on Crush with new nylon L-brackets and the correct propeller configuration to ensure all torque vectors cancel. This way the motors don’t cause unwanted rotation in the water. We also installed a new injector to route the two new thruster cables and servo cable into the battery capsule. Once we verify that the thrusters work and complete ESC characterization so the motors spin the correct way, we will epoxy the injector and make sure everything is still waterproof.

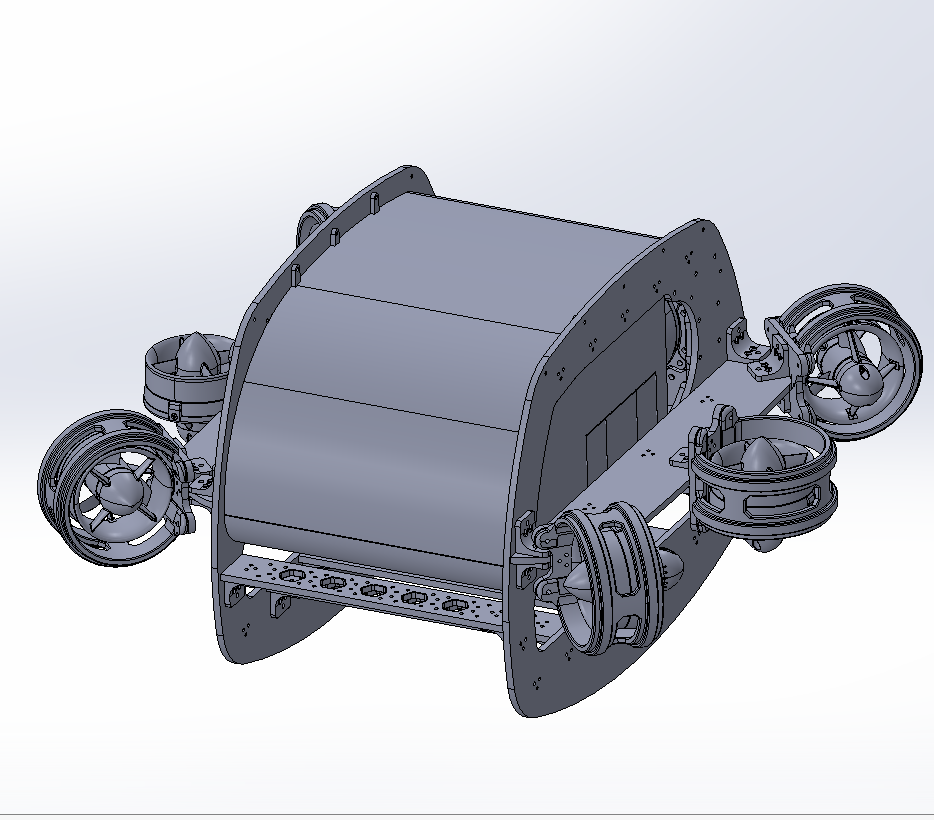

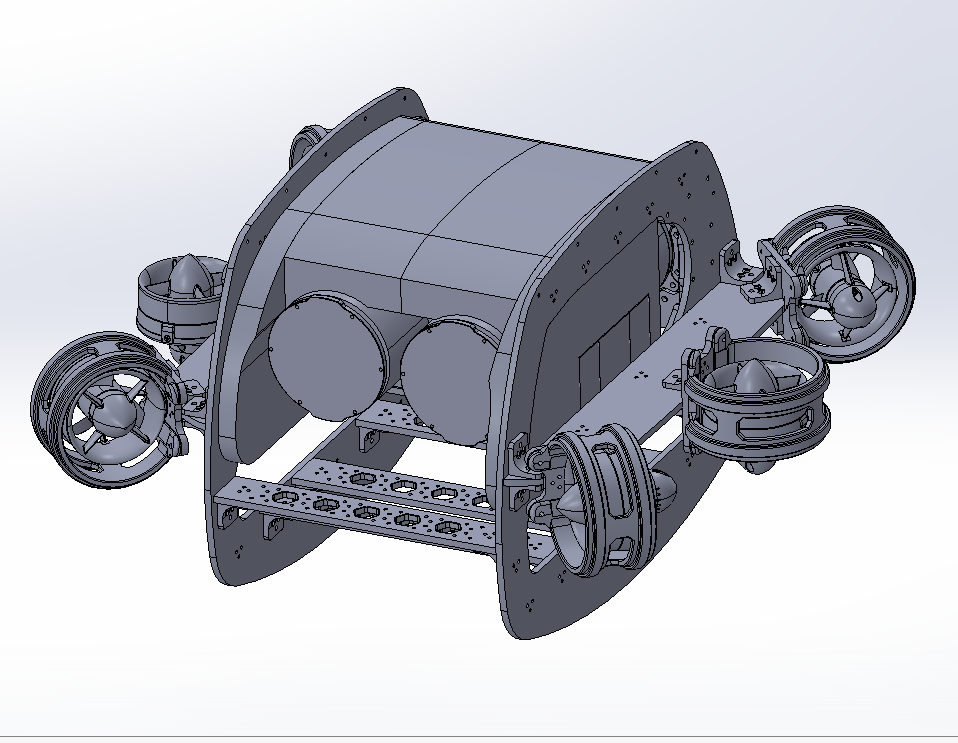

Case and Buoyancy

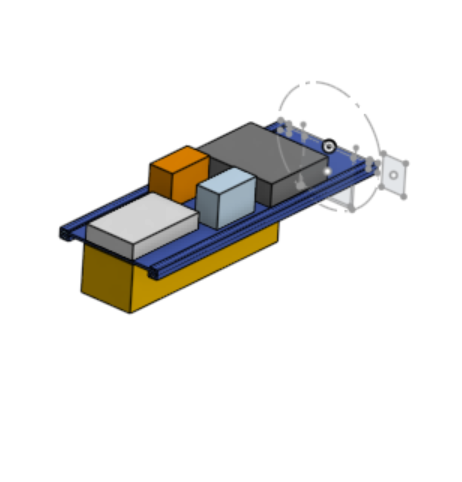

A preliminary mockup of the case has been complete and buoyancy blocks modeled to all fit in the case. This substantially reduces our drag in the water and allows for a more hydrodynamic shape by removing the existing buoyancy blocks that were strapped to the sides and bottom of Crush. In addition, mounts for additional buoyancy on the wing and under the robot have been modeled just in case there isn’t enough buoyancy stored within the final case design. The next step is CFD on the case shape and learning how to use a CNC router to machine the required buoyancy block shapes.

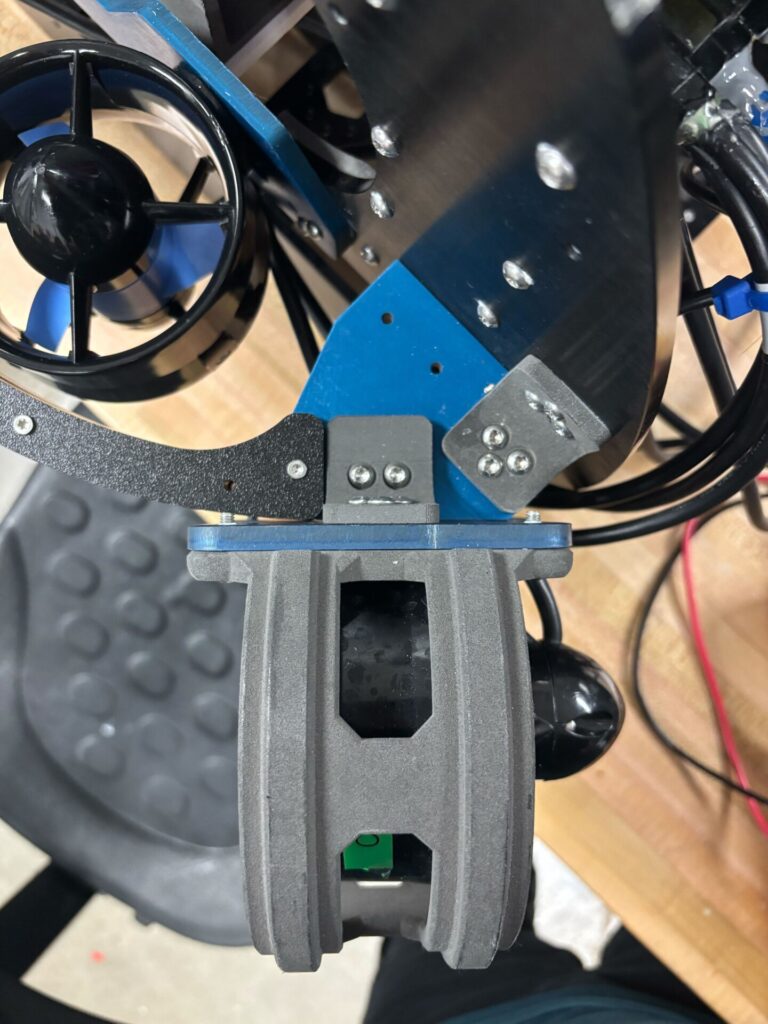

Servo Actuated Gripper & Capsule Design

Our member Ian has been hard at work designing a gripper for the ocean cleanup task where the robot must pick up objects and place them in different bins. A first prototype has already been designed and 3D printed. It utilizes a four bar design, TPU claws, and is actuated by a single servo. This allows for a scooping motion and enough retraction so can be easily incorporated into either robot. Once we get another servo, we can start scaling down the design to fit on Crush and testing the design’s ability to grasp differently shaped objects.

Our previous marker dropper servo that broke has been switched out with a new servo that allows for a larger voltage range and is substantially cheaper. All we need to do now is test if the case keeps the water out and mount it to the robot. Efforts have also been made to redesign the battery capsule on Crush for better modularity and maintenance. Our leading idea involves using only two hex-standoffs with a rectangular mount that allows easy access to all components.

Next Steps

As the first semester comes to a close, the Mechanical team plans to spearhead the redesign of the Crush battery capsule and signal capsule cooling by meeting with the electrical leads. In addition, buoyancy should be complete by the beginning of next semester and enable testing/tuning to begin on Crush. Keep up the good work guys!