The CS team is quite self-sufficient when it comes to running pool tests. New to this semester, we’ve greatly increased the number of pool tests we’re running. Our goal is three per week: Friday morning, Saturday, and Sunday. So, it was not great news to get a (literal) wakeup call on a Friday morning. As an electrical member, this usually means bad things.

At the time, I was sleeping in a tent in K-ville, which is conveniently located just outside of the building where the Duke pool is located. However, due to K-ville rules, I could not walk into the gym, so they brought the robot outside to me.

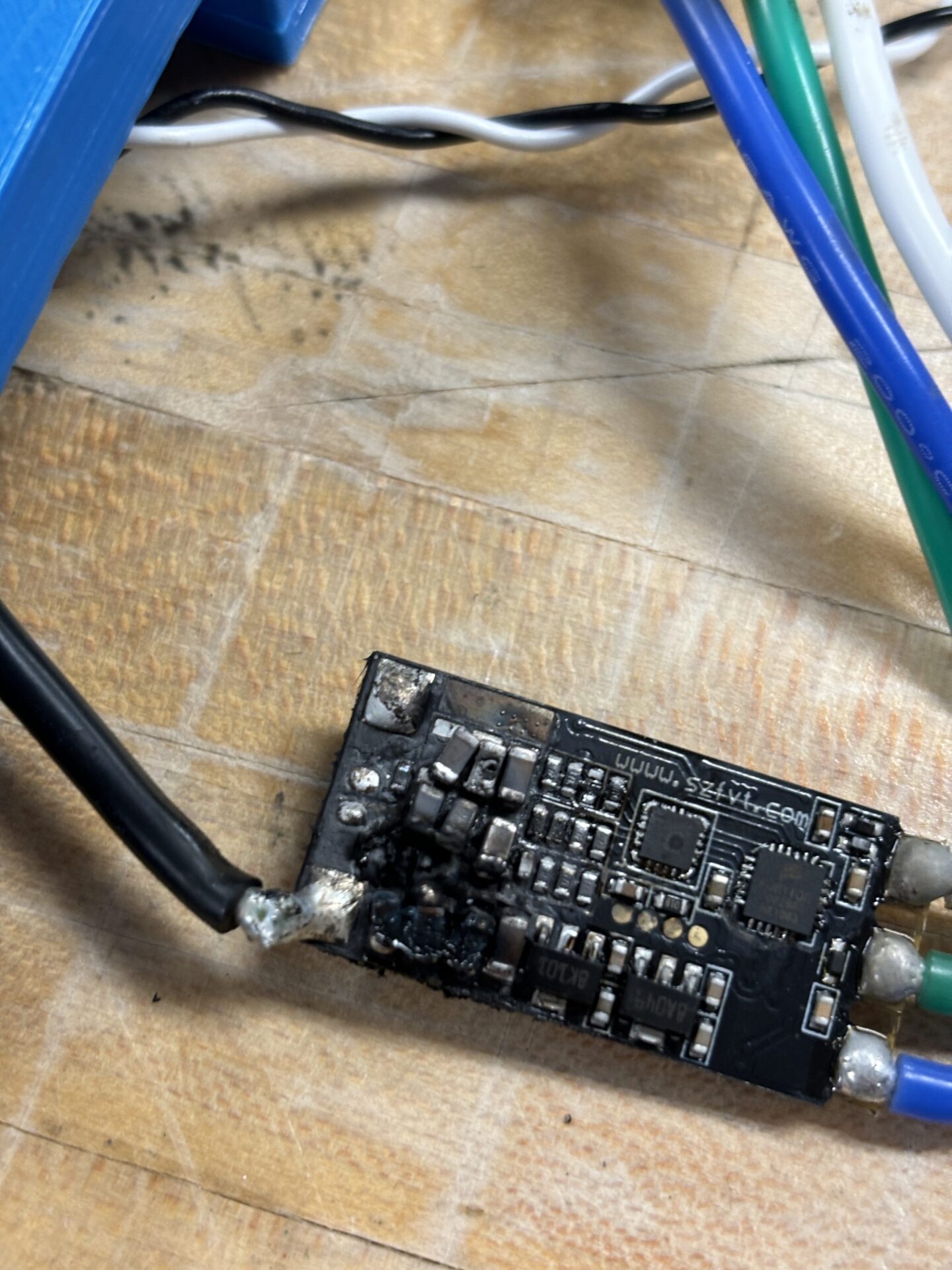

The immediate news with the robot was that the (power) switch was not functioning and that some water had got into the capsule. With a bit of landside debugging, we determined that some USB cables had failed, and the thrusters were a bit inconsistent. However, what we couldn’t see was the apparent water that had really gotten into the stack. Not long into debugging, a large plume of magic smoke erupted from inside the stack, along with sounds of electrical arcing. After an immediate power down of the system and removal of the battery, we knew we were in for a long fix.

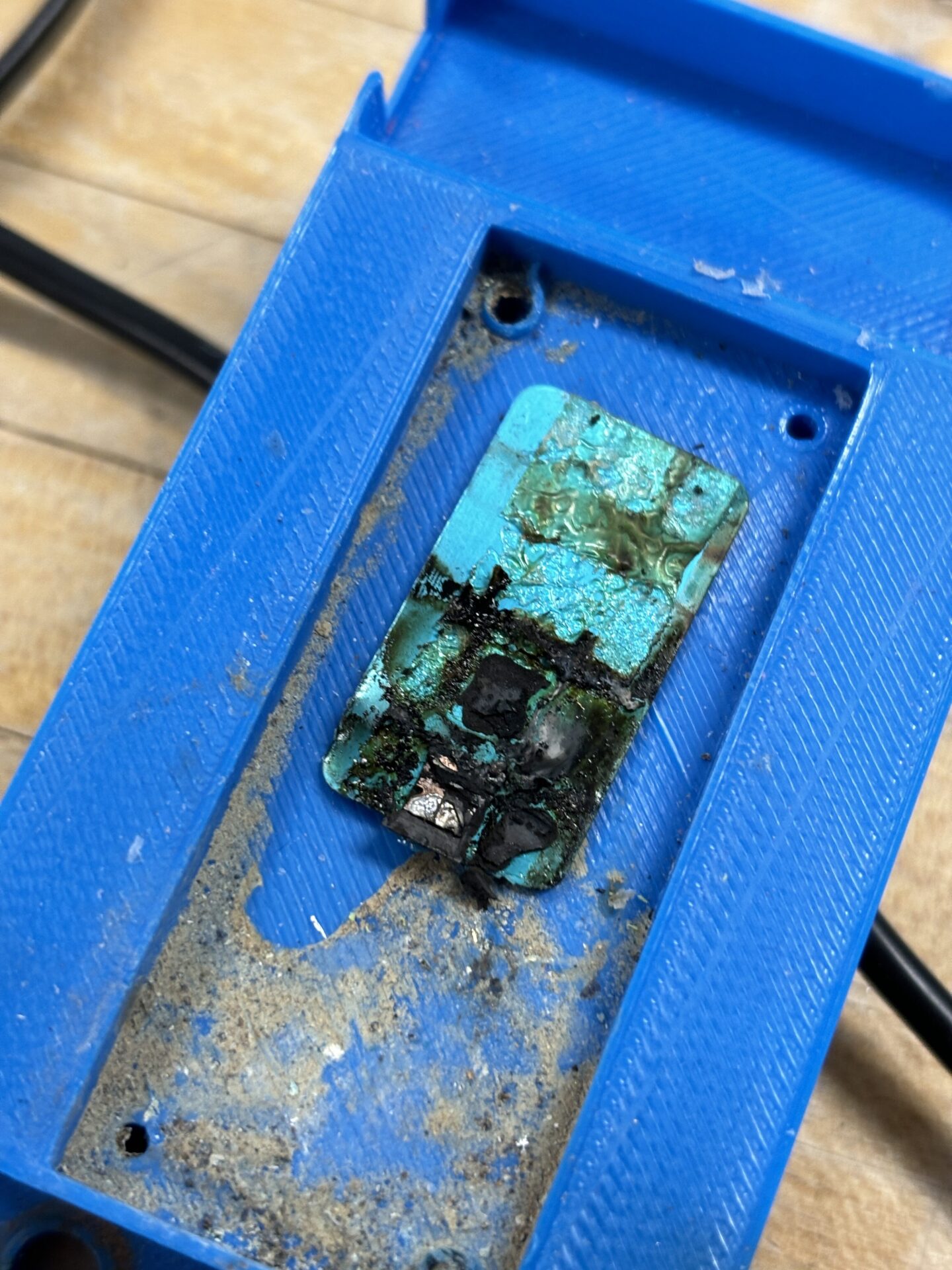

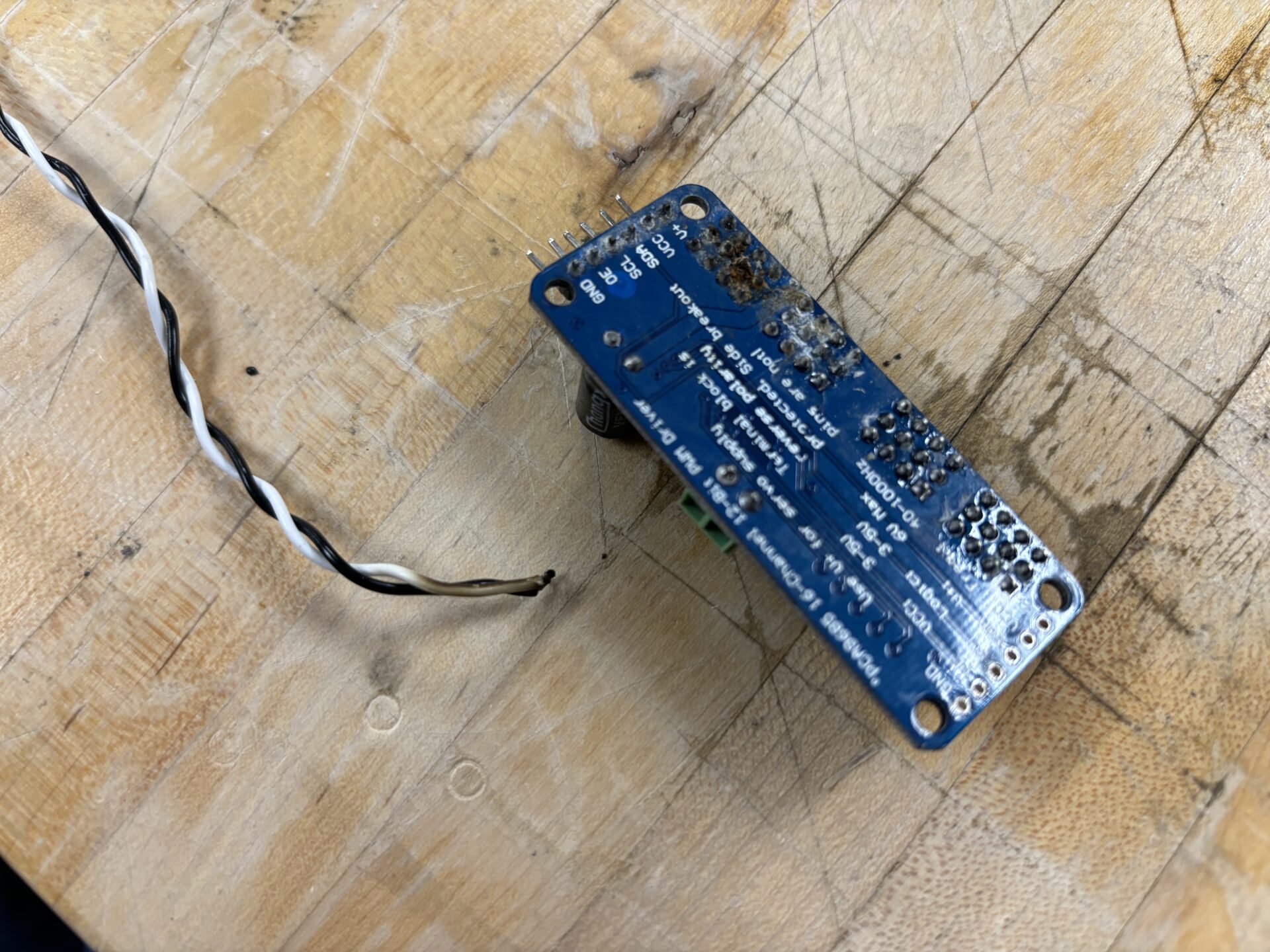

All 8 of our ESCs had been damaged. One was burned so badly, it desoldered its power lead. Water had damaged many components and caused various shorts. Luckily, the most valuable components in the stack (computer, IMU, fiber switch) were undamaged.

Additionally, most of our plate connectors had corroded.

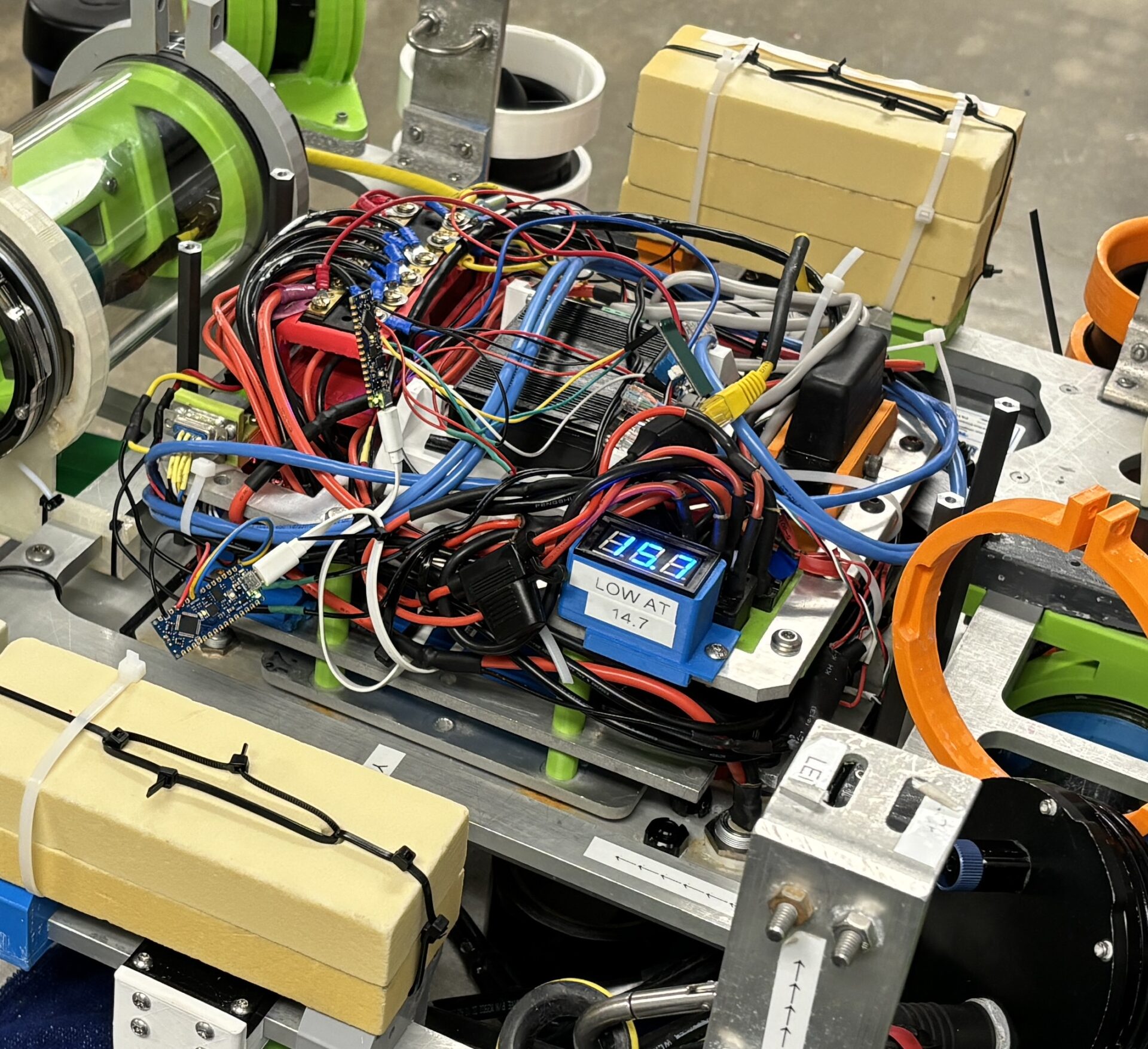

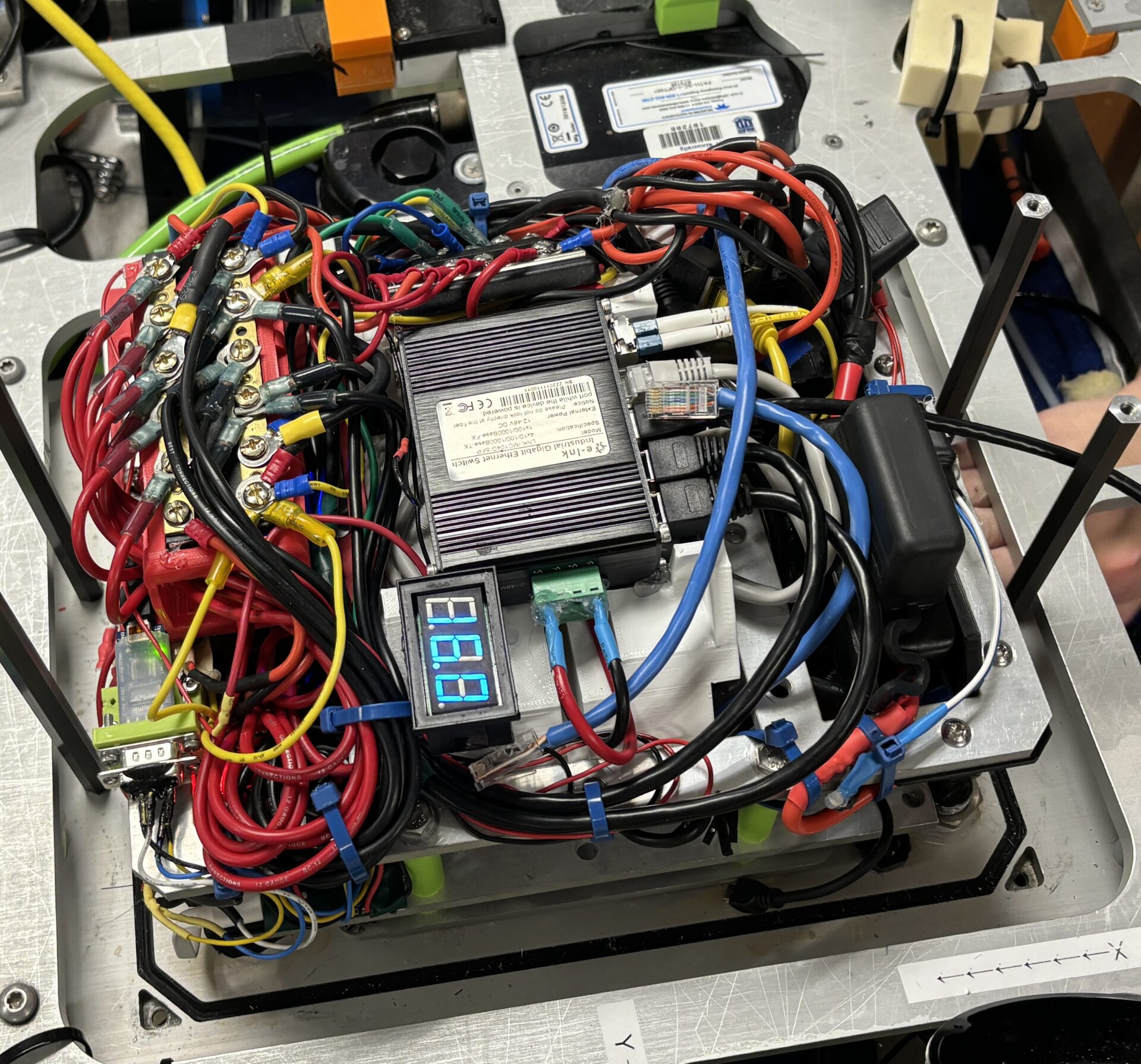

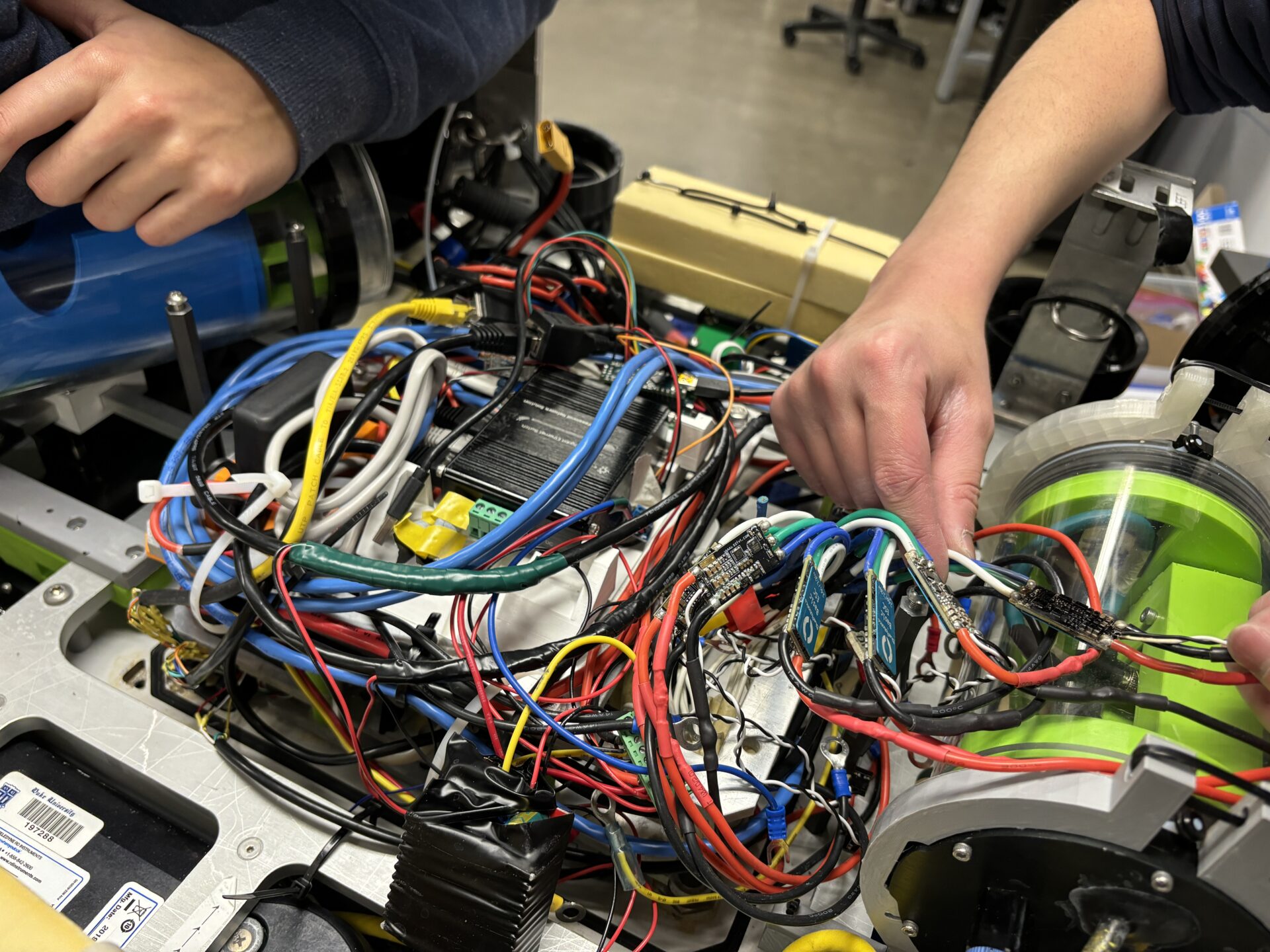

We determined we had to remake the stack. So, we began to remove all the parts to rebuild. Eventually, we got down to the base.

After gathering the necessary replacement parts, we took out the damaged connectors, applied corrosion remover, and in some cases replaced or removed the ports. Next came the long process of rebuilding the stack.

In the interim, we realized the cause of the problem. The capsule simply had not been tightened down enough. With this in mind, we made it a key priority to make the capsule wiring neater and easier to get the capsule on.

While electrical was rebuilding the stack, we gave the CS team a bare-bones version of the system. This included powering the PC and sensors with various power supplies, inspiring us to potentially make an external test rig for future use.

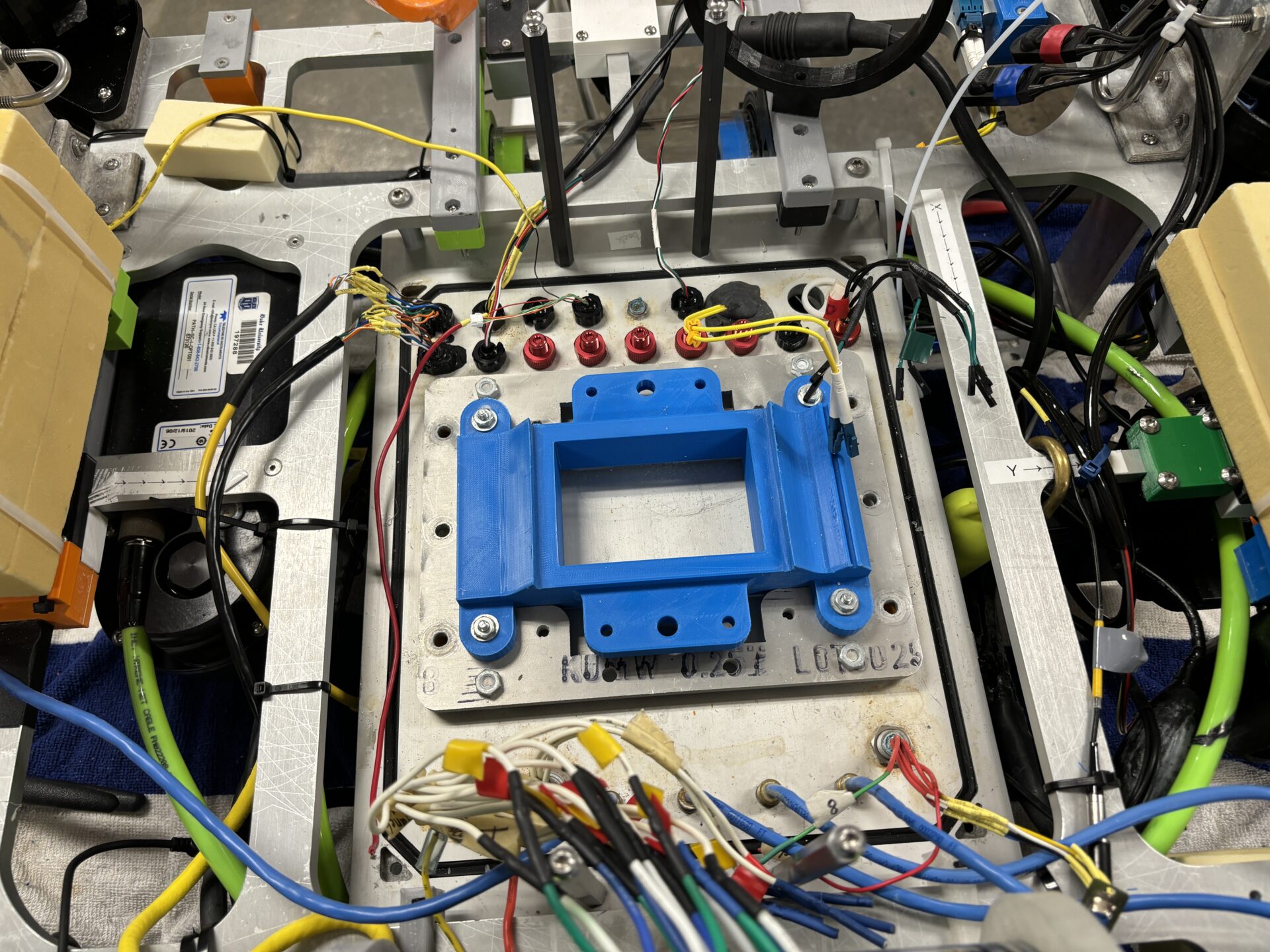

After many long nights, the electrical team had rebuilt the stack, in time for the next pool test. Notable improvements included adding another busbar so that we would have one for each power grid, adding another powered USB hub, and epoxying all plate connectors to prevent corrosion. We also made a big effort to shorten cables as much as we could. While not enjoyable, the stack rebuilding made substantial improvements and the difference is very noticeable and much for the better.