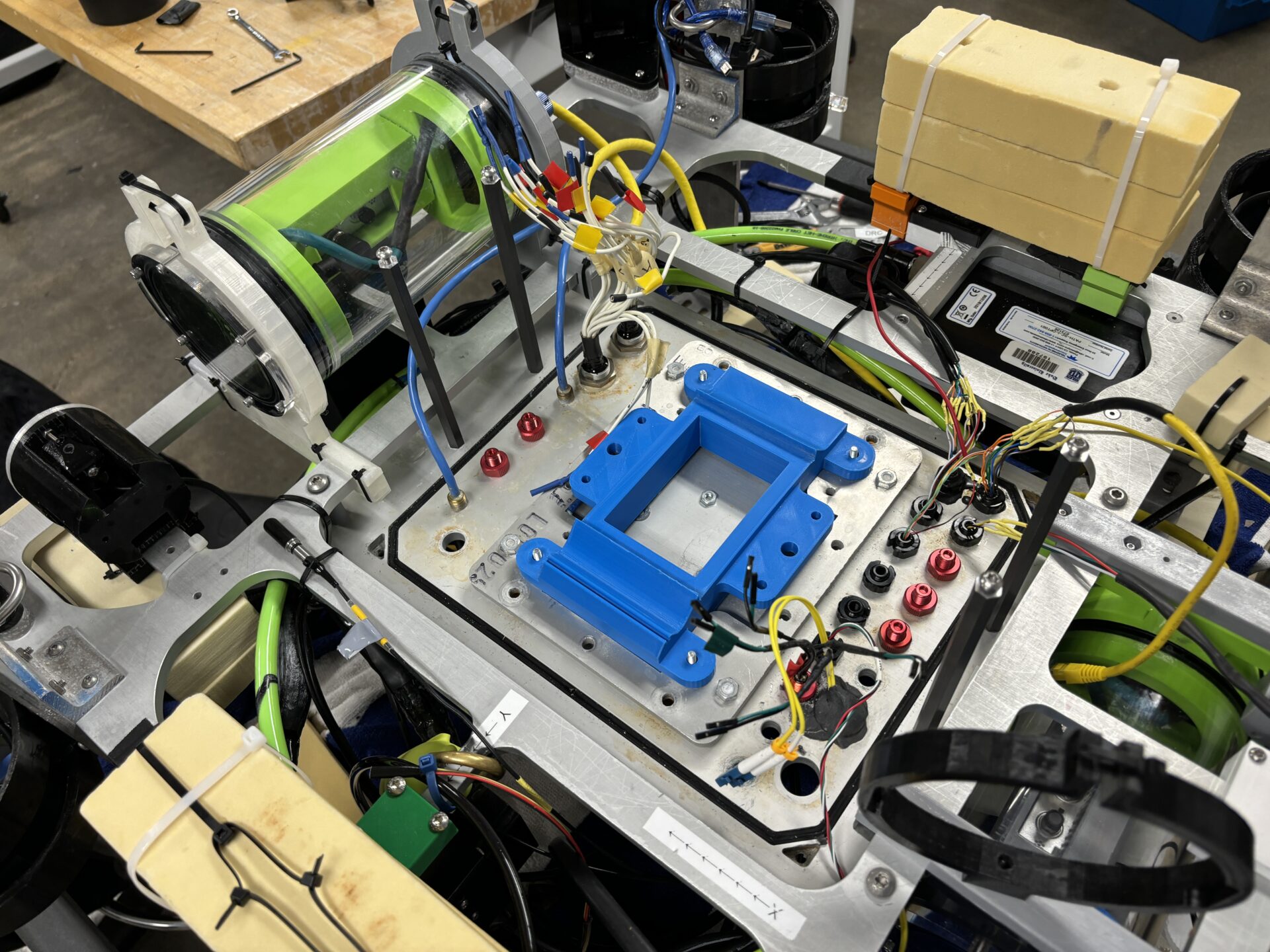

On the first day of March, water leaked into the robot and destroyed many components. We spent a lot of time after this resoldering and re-epoxying different parts of the robot. We also ruggedized the electrical ports in order to prevent future leakages. This is when we decided to implement the temperature and humidity sensor. This would enable us to monitor the internal climate of the robot in the future and prevent major damage due to leakage. By constantly printing temperature and humidity data, we can keep track of any unexpected water inside the robot during pool tests.

At a pool test yesterday, there was another leak in the robot. Luckily, the temperature and humidity sensor recorded this increase in humidity, and we were able to recover the robot before anything broke.