This past week, steady progress has been made on several projects along with the completion of others. Major advances on adding additional thrusters for Crush, marker dropper, new Oogway capsule mounts, case, buoyancy measurements, and a new battery capsule design for both Oogway and Crush

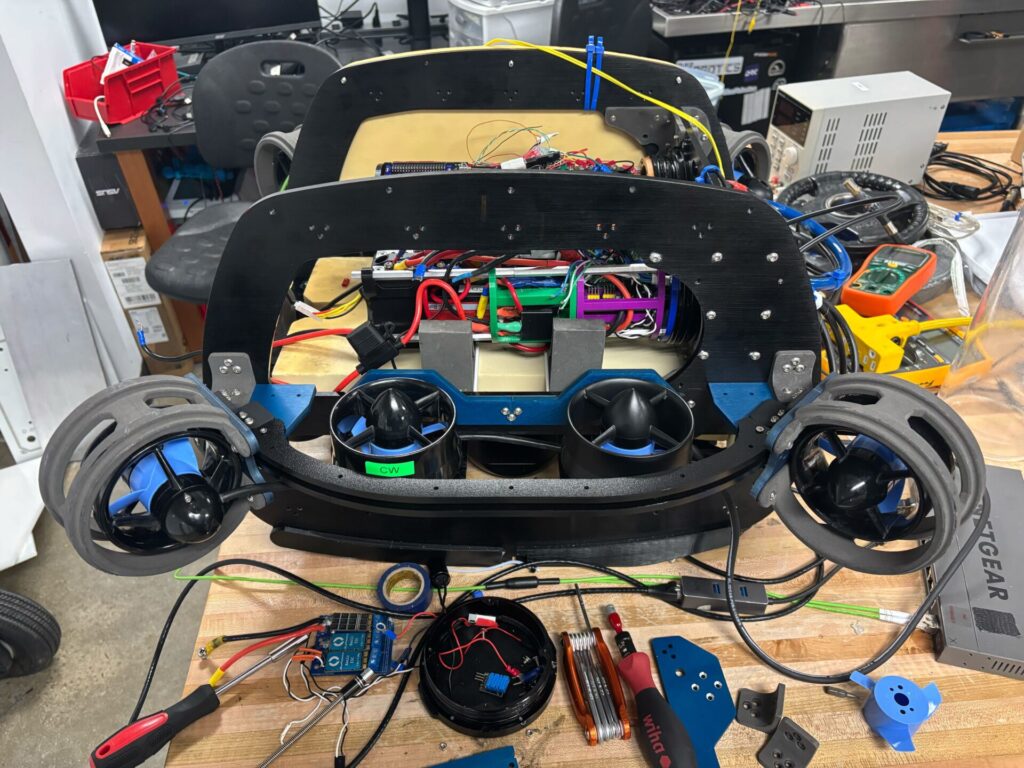

Thrusters on Crush

The parts to add additional thrusters came in, but unfortunately a mistake was made with the hole pattern where the L-bracket attached. All was not lost, with new L-brackets being quickly customized and printed to fit the altered hole pattern. Once countersink holes are drilled for the thruster screws, the thrusters will be able to mounted on Crush as long as no other hiccups occur. Next for thrusters will be integration with electrical and software!

Marker Dropper

The marker dropper is almost complete, with a small compact design that uses a water wheel like system to drop the metal markers one by one. We have also determined the location for the marker dropper to be mounted onto Crush for ease of accessibility, with a custom mount currently in the works. However, there are doubts on whether CS will be able to accurately tune the marker dropper since it is not in the middle of the robot, but we push onwards for now.

Oogway Battery Cable

Good news! The battery cable for Oogway has been up and running. Although the robot almost flooded the first time, we epoxied the injector hole since it was drilled a bit too large. This worked for the last pool test, although minor water leakage has been reported and mechanical will have to investigate.

Smaller Projects

Work is also being done on creating more space in the Oogway battery capsule, where the large PLA handle will be exchanged with two hooks and a durable string. This allows for the cable to wrap around and not place too much stress on the battery connector.

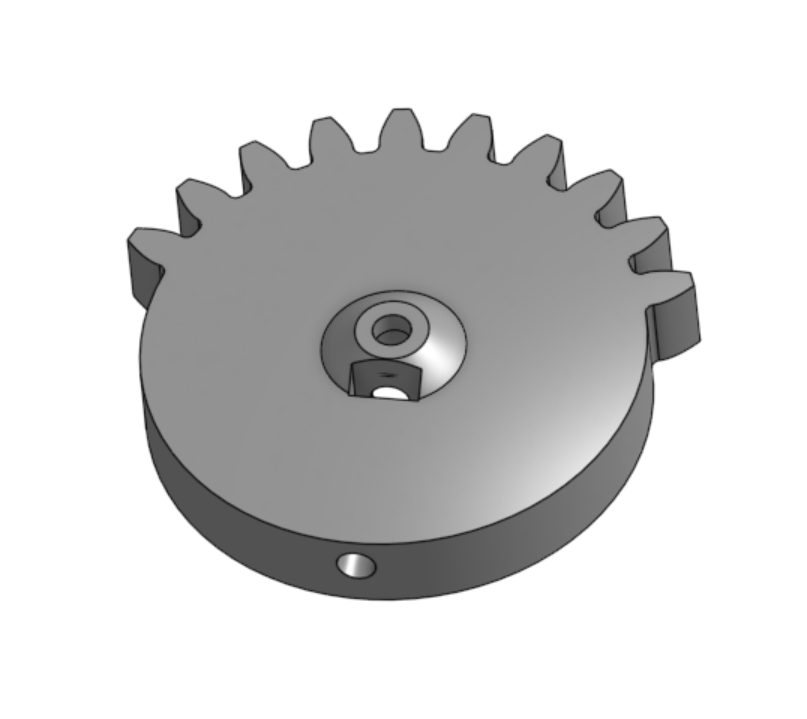

In addition, a grub screw and square nut has been added onto the slip gear for torpedoes. This small change will make the slip gear much more reliable and very little chance of the gear slipping on the shaft.

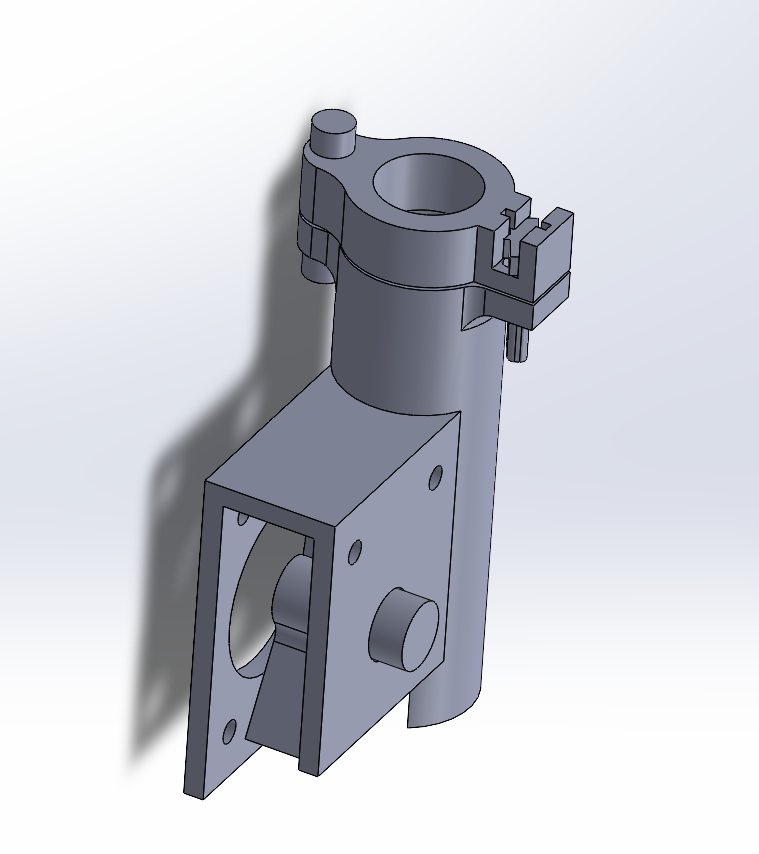

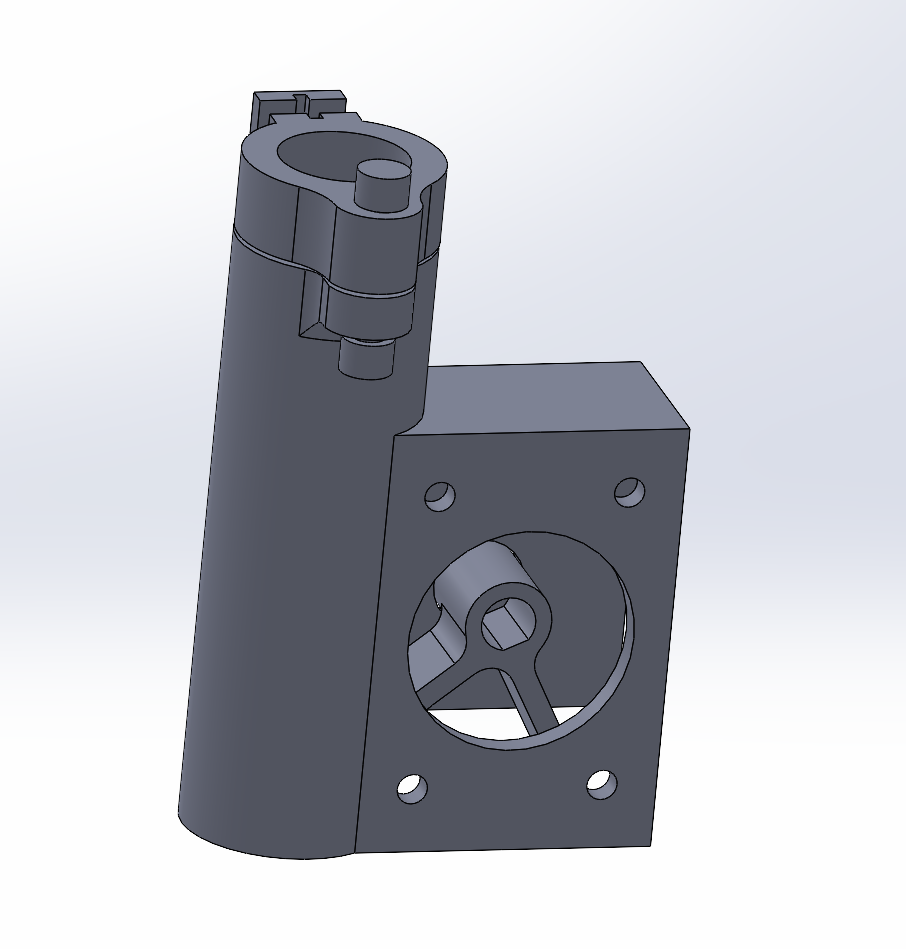

Finally, the sonar mount is getting a redesign to improve access and modularity. This removes the complex steps needed to mount both the front camera and sonar. Next will be finding a way to protect the sonar from getting hit due to its close proximity to the bottom of the robot.

Completed Projects

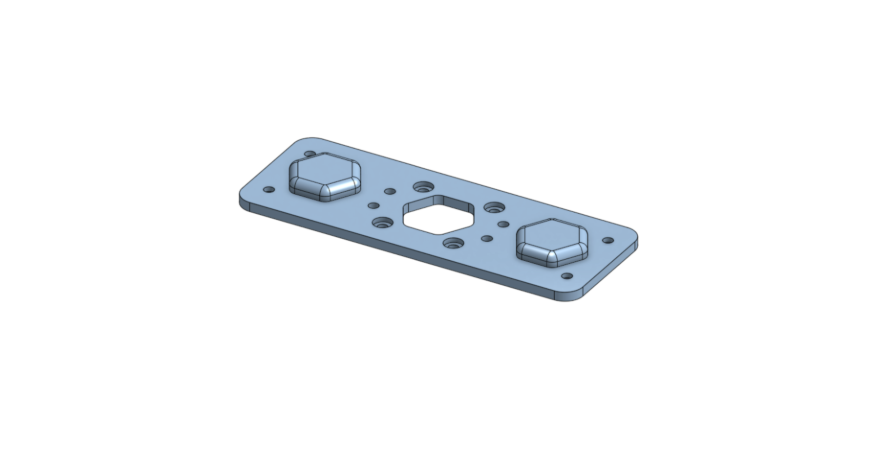

We are off to a good start and multiple projects have already been completed. First is the new Oogway Capsule Mounts that keep the capsules from rotating. They are much more easy to use and robust, which will be great for our goal of reliability this year. All the buoyancy blocks have been measured by Bumjoon, a tedious task that will help us determine how to redistribute the buoyancy once the new thrusters and case are added.

LETS GO MECHANICAL! ⚙️^_^⚙️