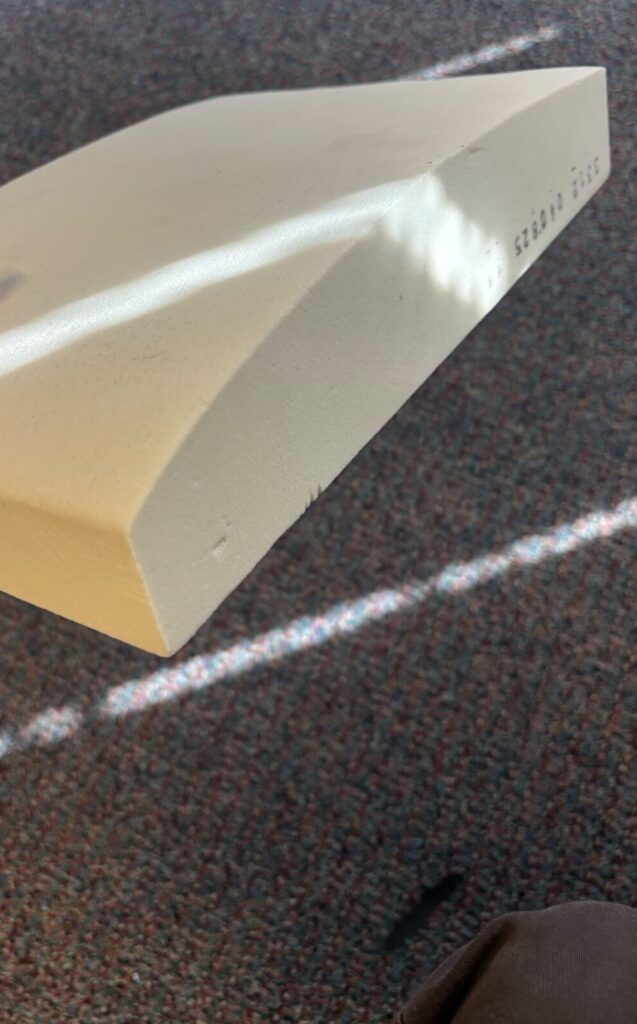

This semester, the primary mechanical focus has been on achieving custom buoyancy, allowing for a sleek case design, improved hydrodynamics, and a more polished overall look for Crush. While machining the buoyancy blocks, we unfortunately experienced an incident that resulted in a part that was less than ideal. Although it was manually cut and sanded down, the final result did not fully meet expectations and will need to be revisited.

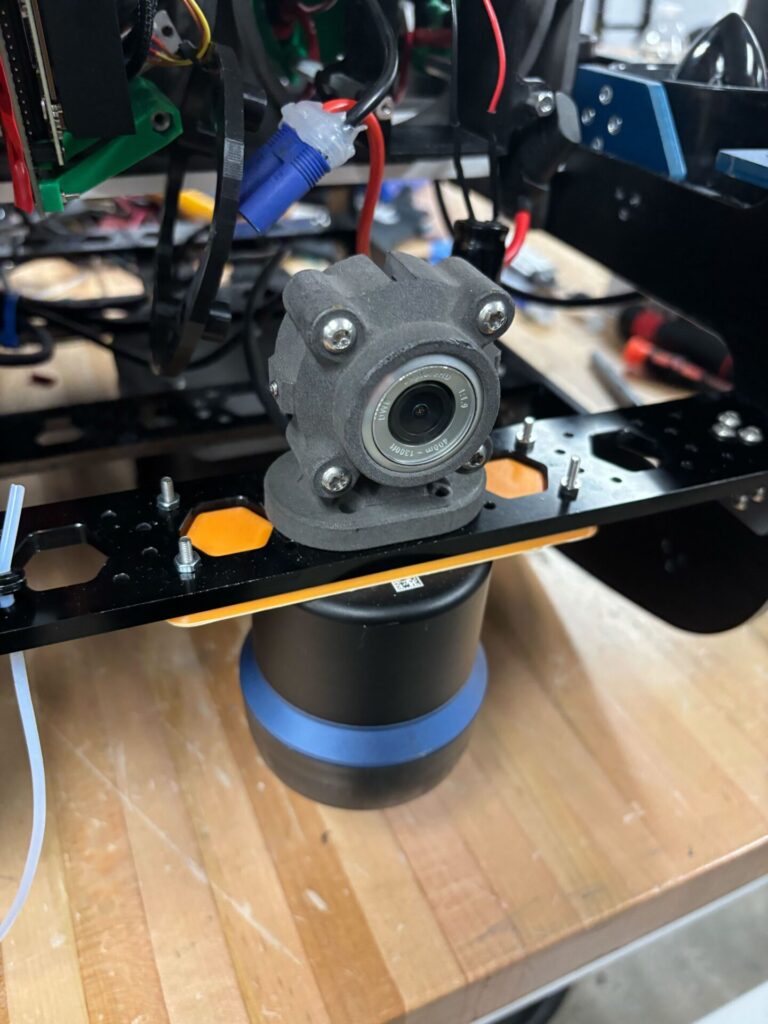

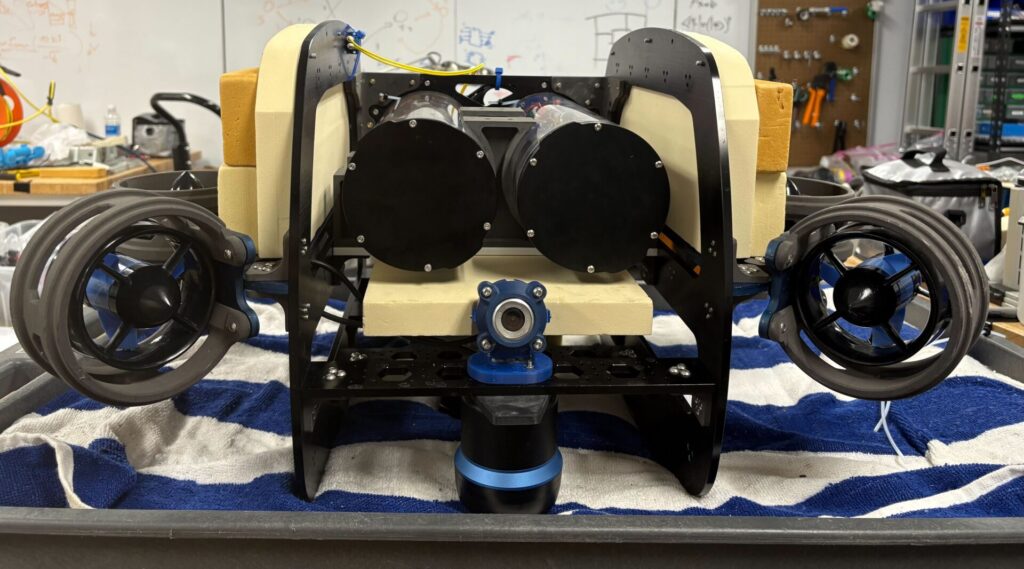

Alongside buoyancy development, several mounting systems were redesigned and improved. A new sonar mount was designed, 3D-printed, and installed on Crush. This updated design features a longer mounting plate that utilizes hex mounting bars and counter-bored holes, allowing the sonar mount to be completely independent from the camera mount. This separation increases modularity and provides greater flexibility when rearranging components.

Similarly, after completing the first iteration of the marker dropper, we identified issues with wiring interference and its distance from the bottom-facing camera. To address this, a new mounting configuration was created that horizontally centers the marker dropper with the camera, improving accessibility and accuracy.

Work has also continued on the gripper design. The team has currently settled on a four-bar linkage design; however, research is still ongoing to explore more compact alternatives that would not require a large servo.

During the most recent pool test, Oogway experienced minor water intake in the main capsule and also the battery capsule. The issue was traced to the internal battery holder, where tension from the wiring was pushing against the seal and allowing water to slowly leak in. Additionally, the O-ring on the main electrical stack capsule was found to be twisted. After correcting both issues, the capsule was successfully resealed, preventing further water intrusion.

Several smaller maintenance tasks were also completed on Oogway, including repairing a broken battery capsule clamp and reprinting parts with extra wall thickness to improve strength and durability.

In parallel, we decided to scrap the idea of placing fans inside Crush and instead ordered new metal capsules. These capsules are expected to improve heat dissipation, and we plan to test them during the next pool session to evaluate their effectiveness in cooling internal components.

Finally, the team has begun initial research toward developing a new robot. Early efforts have included investigating camera options for AI and computer vision, frame designs, CPU specifications, battery hull configurations, and more compact sonar solutions.