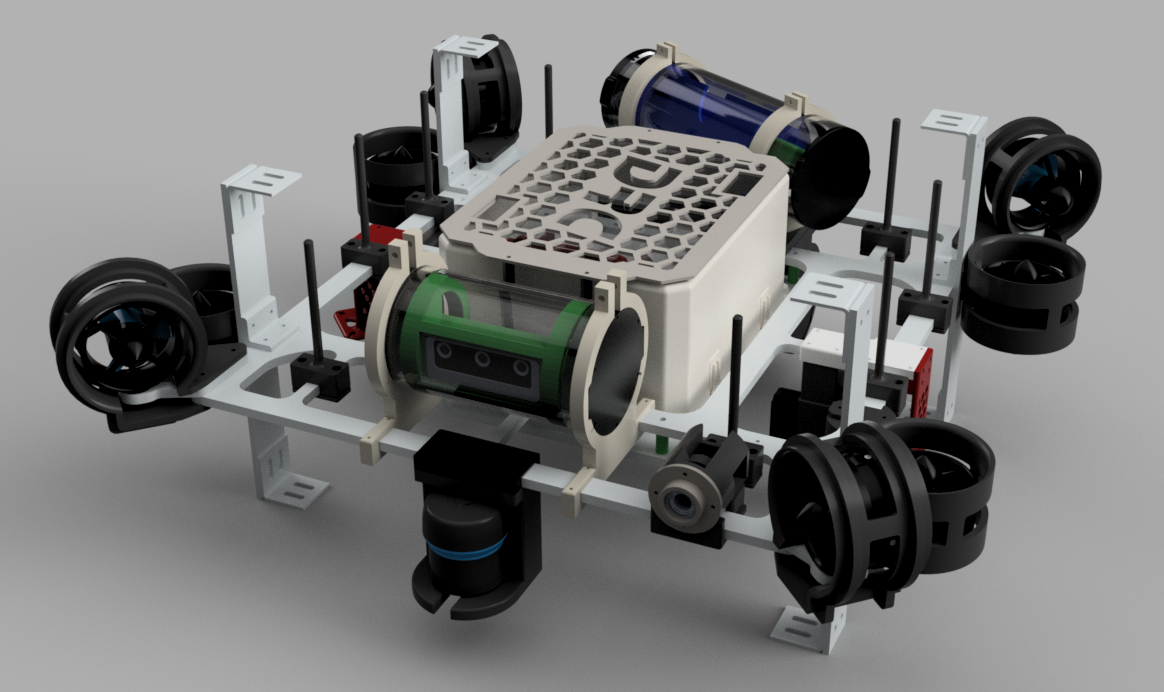

While the main mechanical structure of Oogway has not changed from last year, we improved on old designs based on performance issues from last year’s competition. We also added several new components to enable our robot to accomplish more tasks with more sensors.

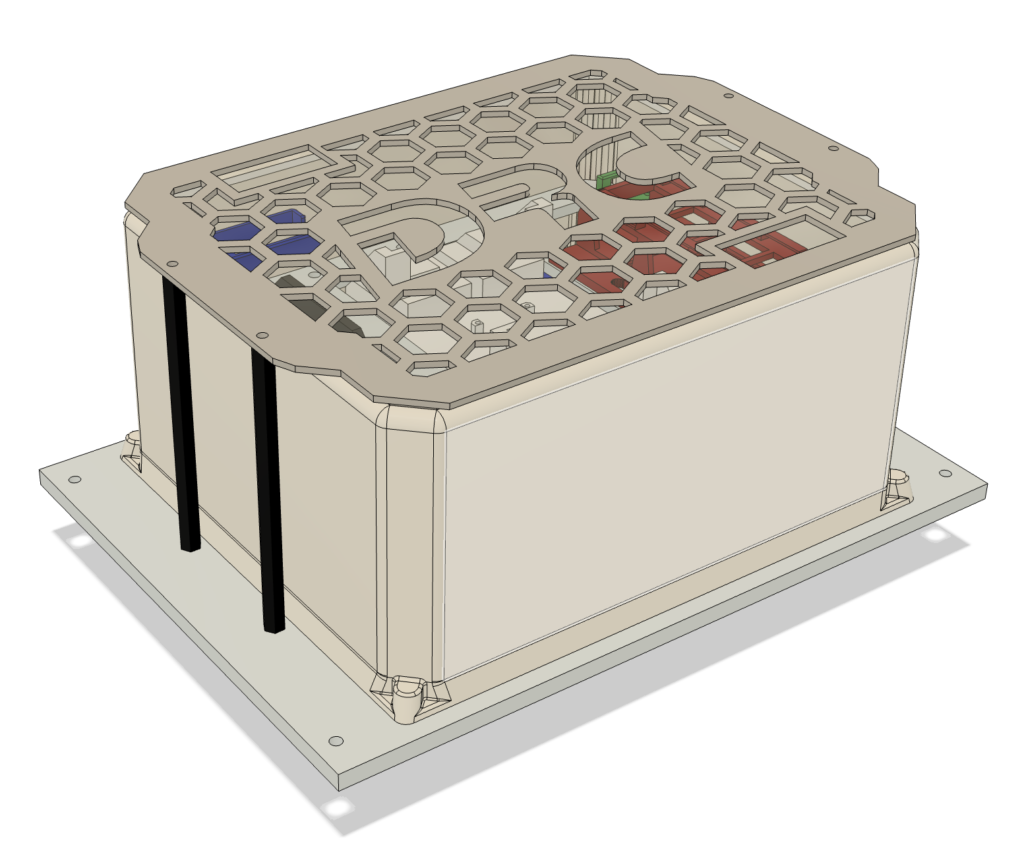

Electrical Stack Capsule

Ensuring the watertightness of the electrical stack is one of the mechanical team’s top priorities. The stack is enclosed by an off-the-shelf Polycase capsule and a custom-machined aluminum plate with space for WetLink penetrators and SubConn connectors. The bottom plate is also anodized to ward off corrosion in saltwater environments.

This year, we added a new custom-made titanium top plate in response to a number of small leaks during last year’s competition. The four brass inserts molded into the Polycase capsule began to fail due to wear and tear over a year of use. The new titanium plate bypasses this weak point and applies even pressure across the entire capsule, improving performance and decreasing deterioration.

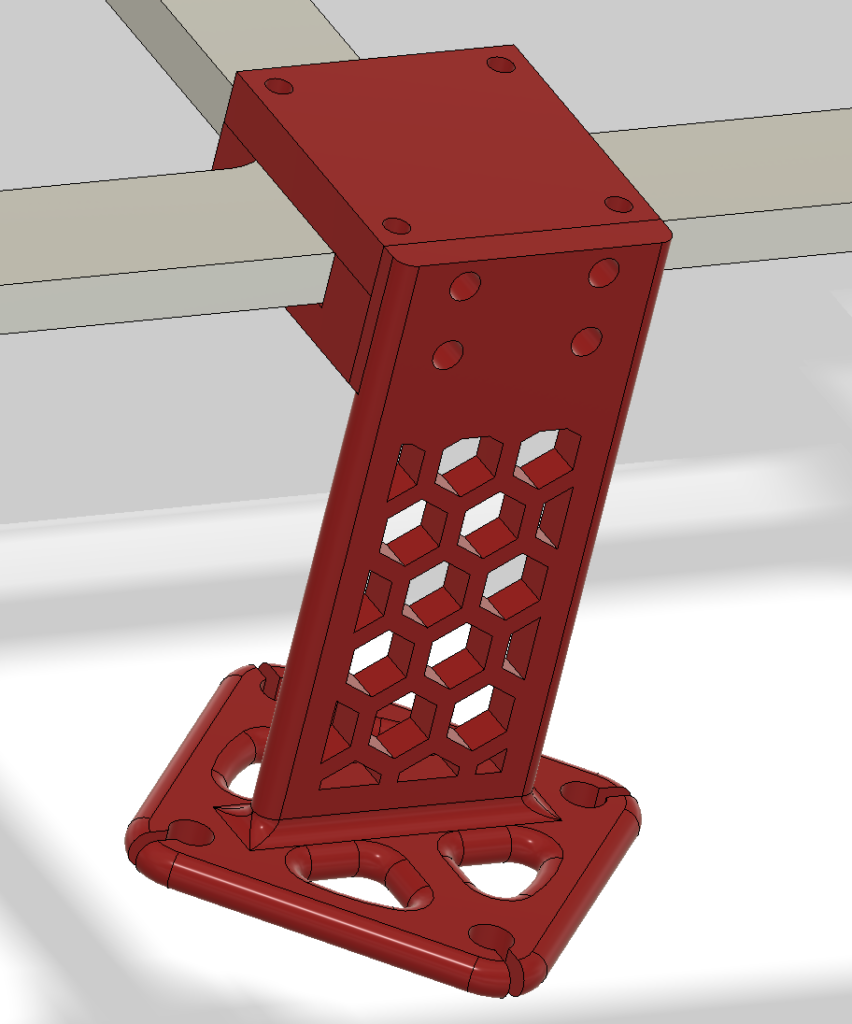

Component Mounts

The primary goals for all component mounts on Oogway are flexibility and rapid prototyping. Oogway’s aluminum rails allow us to move components around easily to optimize for factors such as buoyancy and placement of sensors. This year, this came in handy for the hydrophone mounts, which underwent several different designs and locations as the acoustics subteam developed their code.

We primarily use 3D-printed mounts to keep Oogway lightweight and allow for updated designs to be fabricated consistently and quickly. The battery mount, for example, broke frequently during last year’s competition. This year, we were able to quickly prototype and test new designs and print backups just in case. We also designed several new parts this year, such as a marker dropper, two new sonar mounts, three new camera mounts, and a new adjustable buoyancy system.

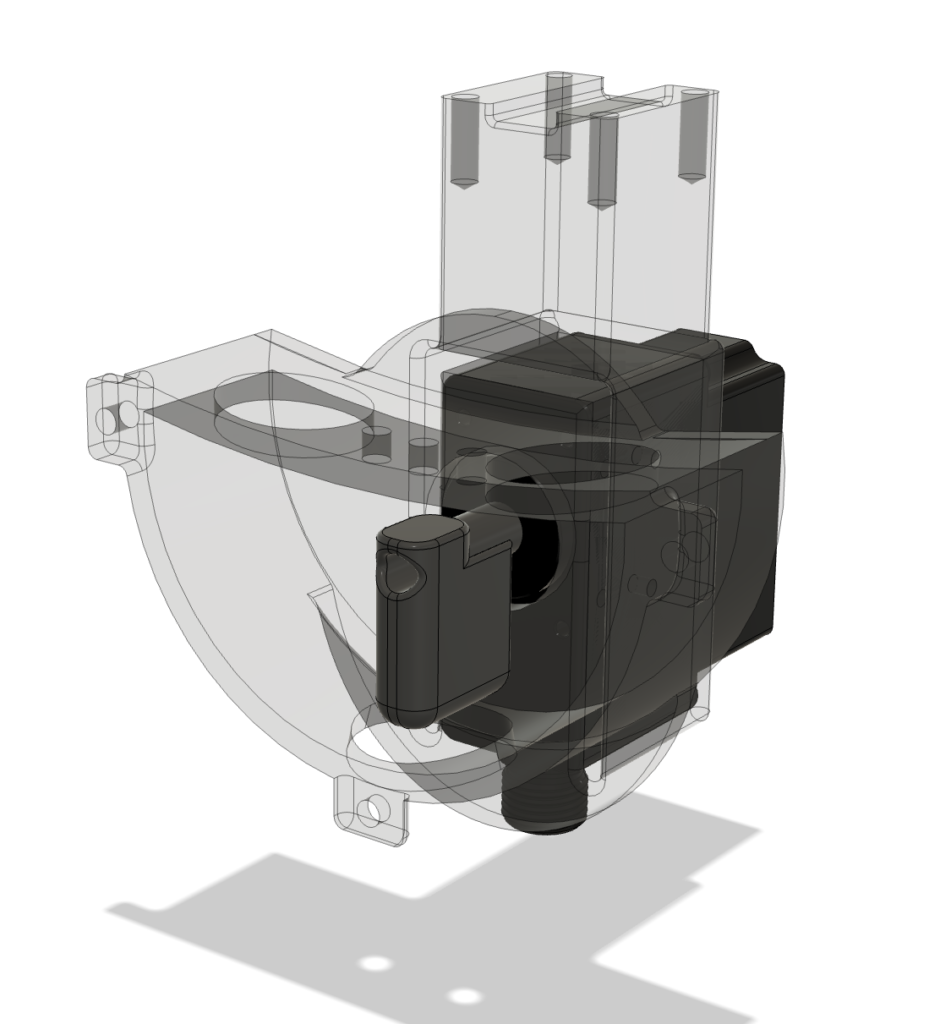

Actuators

We added actuators to Oogway for the first time this year. The marker dropper mechanism uses Blue Trail Engineering’s waterproof servo to hold up to two markers in place, and a rotation to either side allows these markers to be released. This gives us the flexibility to choose when the markers should be dropped and how many should be dropped at a time.

While not yet on Oogway, we are also prototyping a torpedo launcher using the same waterproof servo, which will be responsible for releasing the torpedoes. Like with the marker dropper, we aim to use one servo to control both triggers independently to give us the most flexibility during a run.

Full Model Assembly

As we add or update components on the robot, we also ensure that the full model assembly of Oogway remains up-to-date. The assembly allows us to visualize new components and identify conflicts before fabrication. This year, we also used the full model assembly to generate media materials for the website and paper to more effectively illustrate our prototyping process and final products.

In the future, we hope to integrate the assembly into our simulation workflow. For instance, this would enable our task planning team to roughly tune movement constants before putting the robot in the pool.